Designing the Mesh Network

Apr 11, 2024 · 10 minutes to read

Introduction

Before deploying a mesh network, it is important to learn about key principles of Wirepas mesh networks and solutions to common issues.

When a Treon solution is deployed, it is key to plan the mesh network before the actual on-site installation. While the layout of the deployment environment often defines where the individual sensor nodes need to be placed, it is essential to plan the whole mesh network layout before the deployment, so all data is delivered from the sensor nodes to the backend smoothly.

Information Required:

- Layout of the deployment area

- Intended placement of sensor nodes

- Connection type of Treon Gateway(s) (ethernet, wi-fi, cellular connection) and restrictions of these within the deployment area

- Type of collected data (scalar, FFT or raw data)

Mesh Network Basics

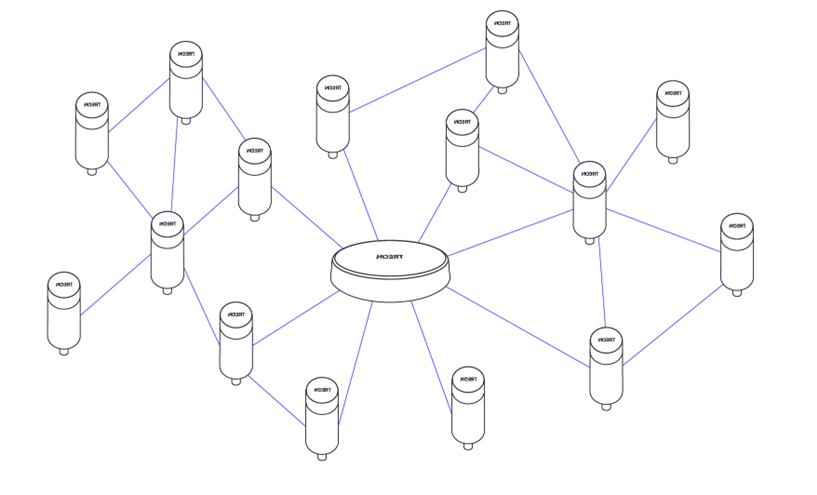

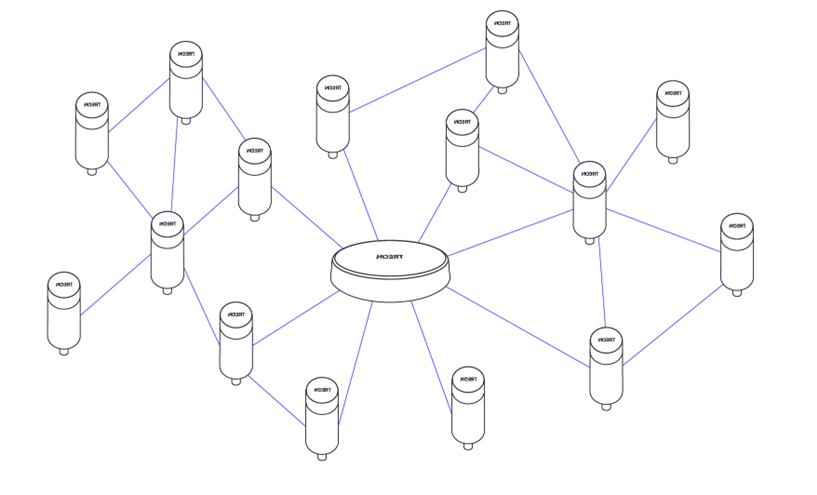

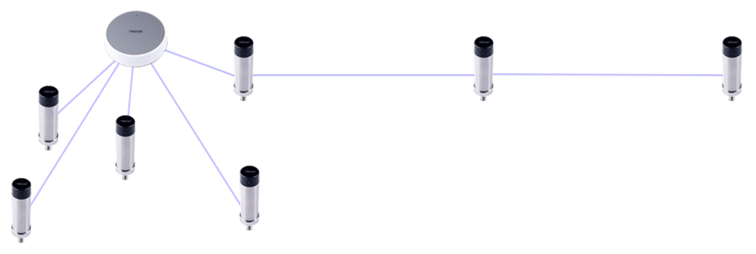

Treon products work on basis of a Wirepas mesh network. This network will establish itself once the Treon Gateway and the Treon Industrial Nodes have been activated and it will form the most efficient connection layout.

Wirepas mesh network. The Gateway transfers the data to the backend.

Key principles of the mesh network

- Treon nodes communicate via Wirepas, a low power network mesh technology.

- In a mesh network, individual nodes transmit their own measurement data and also act as routing nodes, transmitting the data of other nodes. Relaying nodes in a mesh provide the most efficient communication path from all nodes to the gateway and back.

- The mesh network does not have one steady configuration. Instead the way information is routed from nodes to the gateway and back can change as the mesh network continues to keep the ideal mesh network layout. In case you have more than one Treon Gateway in your mesh network, also the Gateway an individual node is transferring data to via intermediate nodes may change.

- All devices within the Wirepas network arranges themselves into the optimal possible configuration of data routing, based on the signal strength between nodes.

- If a device fails or communication is blocked for any other reason, the mesh will automatically re-arrange itself and use alternative routes to communicate with the Treon Gateway and nodes.

- The Treon Gateway can connect to maximum 14 nodes directly and up to several dozen via mesh network.

- All nodes in the mesh network will transfer data. Sensor nodes collect data themselves and forward data for other nodes. Routing nodes are not collecting data and are placed to enhance the mesh network layout and bypass structural obstacles.

Placement of Devices & Optimal Layout

Optimal Order of Deployment

When you look at the layout of the deployment area, the first information you have are the locations of the sensor nodes. They need to be installed in the places where they need to collect data. From this starting point you can plan where the Treon Gateways and possible routing nodes need to be placed.

For the best performance, place the gateway in a way that as many sensor devices as possible are directly in its range. The Treon Gateway supports connection to up to 14 nodes directly. This way, the nodes closest to the gateway will not become congested with routed data, and the network can automatically optimize data routes. The ideal layout of a mesh network is an actual mesh.

Range of Treon Industrial Nodes

The maximum distance between the Treon Gateway and the nodes, and in-between nodes, can vary from a few tens of meters to up to 60 meters, depending on the individual deployment environment. A clear line of sight between devices will help a longer distance and optimal conditions for radio transmission.

Specifically in an industrial environment with metal structures and walls, the conditions for radio transmission might not be optimal and the range can be limited to a few tens of meters. In this article we offer strategies on how to work also in a industrial and other complex environments, how to bypass structures and create a well-designed mesh network in any kind of environment!

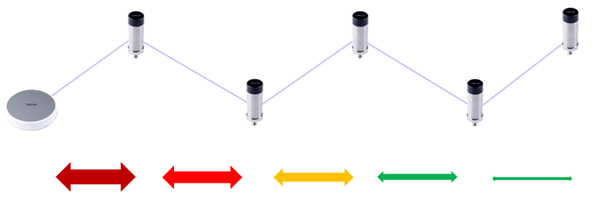

Short Routes

The data from each individual node should be able to travel to the gateway in the shortest possible way.

Gateway to Node Ratio

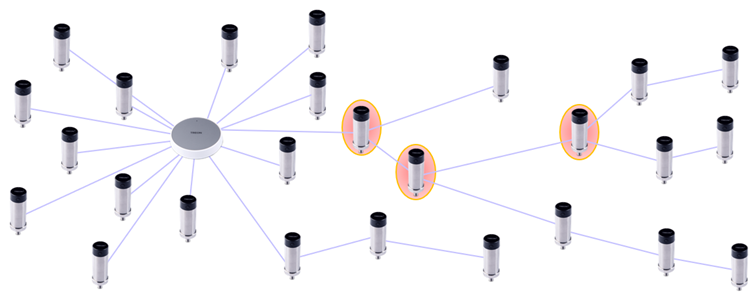

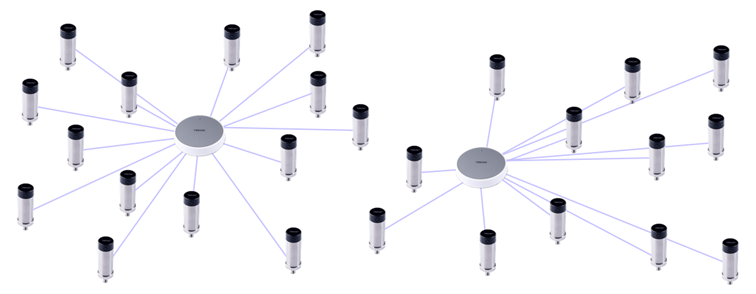

When designing the mesh layout, it is important to consider the amount and the location of the Treon Gateways in the deployment area.

The Treon Gateway can connect up to 14 nodes directly, and up to tens of devices via the mesh network. Depending on the data amount transmitted from the nodes to the gateway, we recommend deploying a second gateway at the latest when more than 50 nodes are connected. This will make sure that all your data is flowing from the nodes to your backend without interruption.

Please note that it is a key aspect of designing the mesh network to avoid long routing pathways in your layout. Individual nodes that transmit the data for multiple other nodes can cause problems. A large amount of data can congest the network traffic, and you might not receive all the data from all sensor nodes in the expected timeframe, or not at all. Transmitting data for several other nodes also needs more power and will lead to a lower battery life expectancy for the routing node. If the planned layout seems likely to create such ‘super-routing nodes’ in the mesh network, please consider adding another Treon Gateway instead.

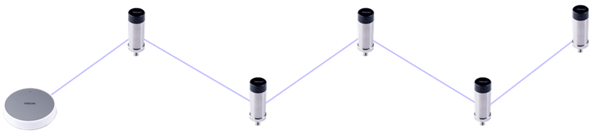

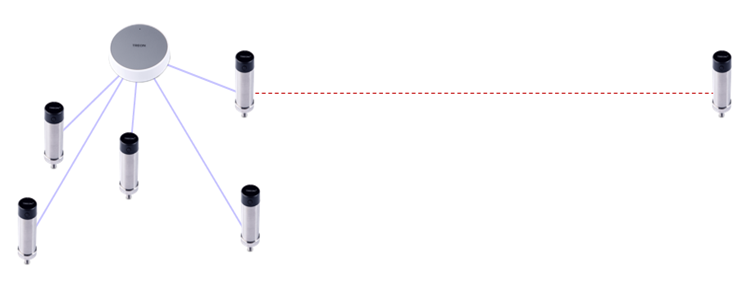

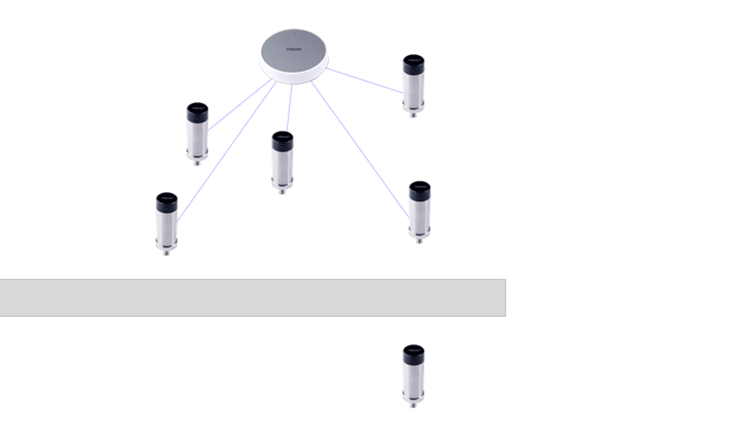

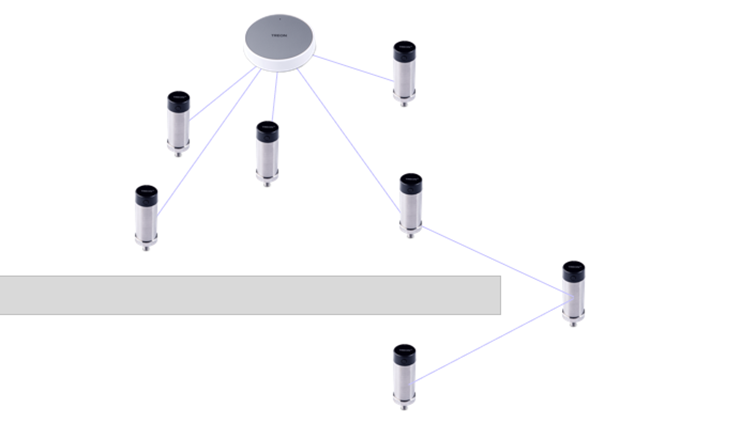

Gap Bridging

If the gateway and nodes are too far apart for efficient data transmission, place one or several routing sensors between them to transmit data from one node to another. Avoid layouts where one node routes the traffic from several other nodes. This may happen if a group of sensor nodes is too far from the gateway or placed in a long line. Optimally, the sensor nodes should have multiple routes for sending their data to the gateway, meaning each sensor nodes should be in reach of several other nodes.

Please note that if you add more nodes or gateways to your mesh network later, the entire mesh will reorganise itself. This process may take a few hours. However, the nodes continue to operate at the same time.

Routing nodes are nodes that are set up to not collect measurements and to only route data from other nodes and need a specific configuration from Treon.

Bridging gaps with long single chains of routing nodes, even when transmitting the data from only one sensor node, should be avoided when deploying an additional Treon Gateway close to the sensor node is an option.

distances between individual nodes in a mesh network, it can also help bypass structural issues that keep nodes from communicating. Thick walls and large metal objects might block the signal and can be circumvented by installing an additional node to act as a forwarding device and connect devices behind the obstacle to the mesh network.

When planning your mesh network, it is not always clear that you need gap bridging nodes. Depending on the individual three dimensional layout in the deployment area, and depending on surface and core materials of structures, a signal might be bounced farther than expected or blocked closer to another node than anticipated. Often only the on-site deployment will show that a node cannot connect. Always be prepared to place additional Treon Gateways and routing nodes if that happens.

Impact of Routing Large Data on Mesh Network Performance

An important factor when designing the layout for a mesh network is the amount of data that will be transmitted through the mesh network to the Treon Gateway.

In general, we distinguish between:

- Scalar data: few data fragments create little traffic in the mesh network.

- Burst data: FFT and specifically raw data crate thousands of data fragments that might potentially cause issues in the mesh network.

If you want to route burst data, please consider:

The more sensor measurements are triggered at the same time, the more traffic will be through the mesh network. Triggering measurements and sending raw data at different times can help solve this.

If the data from several sensor nodes has to pass through a single node, it is more likely that data congestion will occur, and measurement data can be lost. Routes through the mesh network should be short, and enough end points in the form of Treon Gateways are essential.

Please read more on this topic in this article on large data in mesh networks..

Impact of Routing Data on Node Battery Life

Next to basic operation and sensor measurements, transmitting data has a high impact on the node’s power consumption and is the biggest drain on the battery lifetime of the Treon Industrial Node.

While transmitting scalar data has much less impact on battery lifetime as fewer data fragments need to reach the gateway, transmitting FFT and specifically raw data can create issues when the data of several sensors is routed via an individual node.

Signal Strength (RSSI)

The signal strength between the nodes in the mesh network, and between the nodes and the gateway, only have an influence on data throughput in case the link quality is rather bad. If the RSSI is bad, messaged can be lost and then need to be resent from node to node, which means the throughput will go down. In case you use the Wirepas Network Tool (WNT), you can check the link quality between the nodes. It is recommended to have a value of 80 % or higher. Below this value, data might not get through and even updates of the nodes might fail.

The recommended values provided by Wirepas are the following:

| RSSI Limit | Description |

|---|---|

| >= -60 dBm | Excellent. |

| -75 dBm <RSSI <-60 dBm | Good. Recommended from here and up to ensure stability. |

| -80 dBm < RSSI < -75 dBm | Average. KPI’s will work fine. FFT and Raw data might experience issues on larger networks. Depending on the use case this setup can be stable enough. |

| -85 dBm < RSSI < - 80 dBm | Bad, unstable connection not recommended for large deployments. KPI’s will work OK, FFT and Raw data are likely to drop packages. |

| RSSI <= -85 dBm | No connection. |

Treon Support

You still have questions? Our dedicated team of experts is happy to help you! Please contact Treon Support directly by e-mail.

Did you know? Treon offers Premium Support and Maintenance Packages for our customers. Get even more out of Treon and boost your sales - inquire now about features and prices!