Positioning a sensor

To detect abnormalities in machine components, install Treon sensors in locations where temperature and vibration can be measured effectively.

Best Practices for Sensor Placement

Mount directly on the housing of the target component for accurate readings.

Minimize the vibration transmission path — the distance between the vibration source and the sensor.

Avoid mounting on flexible or resonant surfaces, such as sheet metal covers, which can oscillate and distort measurements.

Vibration attenuates up to 75–90 cm (30–36") from the source.

Attributes of the vibration transmission path that can reduce the transmission path length include:

- The number of mounting surfaces, which can cause signal reflection.

- Materials like rubber or plastic can absorb vibration and reduce accuracy.

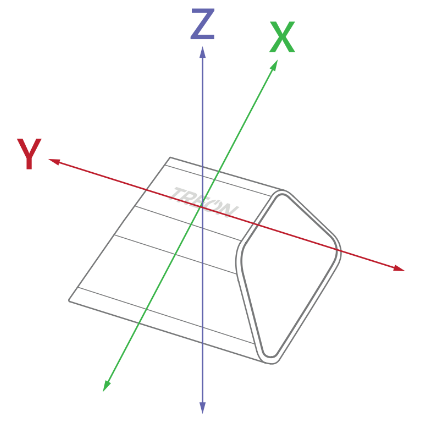

⚠️ Treon Industrial Node C sensors measure vibration on three axes (X, Y, Z). These axes are marked on the sensor body. You do not need to align a specific axis with the machine’s vibration direction.

Examples of Sensor Placement

Electric Motor

- Two sensors on the motor

Place sensors close to the primary vibration source. For gearboxes, consider how vibration transmits through connected components. For bearings, position the sensor near the load zone (the area under the most stress).

ℹ️ The shortest distance to the vibration source is not always the best location. Consider how vibration travels through the machine structure.