How to install Treon Industrial Node C sensors

Introduction

This article explains how to mount the Treon Industrial Node C on assets.

The Treon Industrial Node C is mounted on monitored equipment by gluing it.

Sensor location

It is important to consider the location of the sensor and the contact between the sensor and the equipment, when mounting it to monitored equipment. The best location to mount the sensor depends on the monitored equipment and the vibration source.

Typically, on rotating equipment sensors are mounted on equipment housing close to bearings avoiding placement on partially or loosely connected parts that can resonate on non-relevant frequencies.

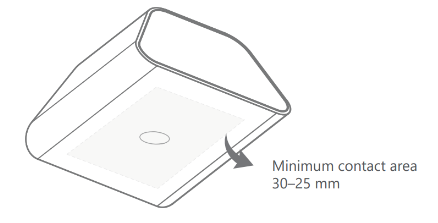

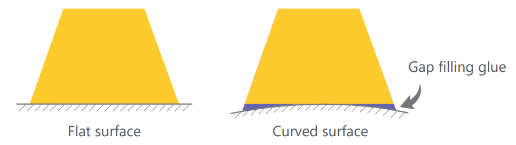

For best measurement quality, the sensor is glued on a completely flat and smooth surface larger than the base of the sensor. At minimum, one-third of the sensor base should be fixed to the asset. The mounting surface needs to be cleaned of all oil, grease or other dirt prior to mounting.

Best Practices for Sensor Placement

Close to the Vibration Source

Mount the sensor as close as possible to the primary vibration source (e.g., bearings, gearboxes, or motor housings). Avoid mounting on covers, guards, or thin panels that can introduce resonance and distort measurements.

Rigid and Solid Surfaces

Choose a location on the machine that is rigid and directly connected to the component being monitored. Avoid surfaces that flex or vibrate independently of the main structure.

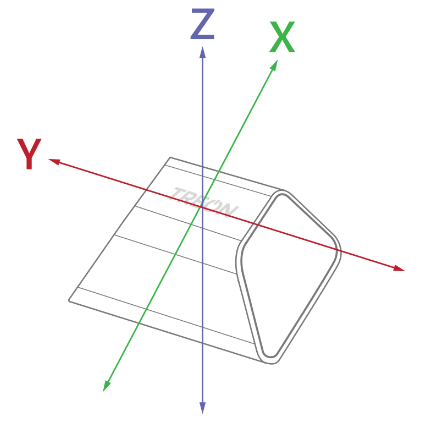

Orientation Ensure the axes are aligned consistently across machines for comparable data. Typically, the Z-axis should point along the shaft axis or vertically, depending on your monitoring strategy.

Avoid Heat and Moisture

Do not place sensors near high-temperature zones or areas exposed to oil spray, coolant, or condensation.

Accessibility

Position sensors where they can be easily accessed for maintenance or replacement without dismantling major machine parts.

Examples by Machine Type

Electric Motors: Near the drive-end bearing housing.

Pumps: On the bearing housing closest to the impeller.

Gearboxes: On the casing near the input and output shafts.

Fans: On the bearing housing near the fan blade assembly.

Adhesive

Industrial adhesives such as Loctite 454 can be used to mount the sensor on a flat and smooth surface. If the surface is slightly curved or uneven, a slightly thicker layer of adhesive such as Loctite 3090 or 4070 can be used for gluing the sensor.

Follow closely the instructions that comes with the glue.

Aligning the sensor

For accurate interpretation of the measurement data of all sensor axis, the centerline of the sensor is typically aligned with the shaft of the rotating machine. When mounting the sensor, align its axis directly toward drive or non-drive end of monitored achine in line with its shaft