Mounting Sensors on Assets

The Treon Industrial Sensor C is mounted on monitored equipment by gluing it.

Sensor location

It is important to consider the location of the sensor and the contact between the sensor and the equipment, when mounting it to monitored equipment. The best location to mount the sensor depends on the monitored equipment and the vibration source.

Typically, on rotating equipment sensors are mounted on equipment housing close to bearings avoiding placement on partially or loosely connected parts that can resonate on non-relevant frequencies.

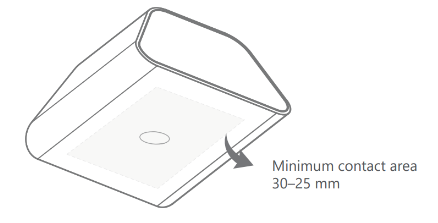

For best measurement quality, the sensor is glued on a completely flat and smooth surface larger than the base of the sensor. At minimum, one-third of the sensor base should be fixed to the asset. The mounting surface needs to be cleaned of all oil, grease or other dirt prior to mounting.

Adhesive

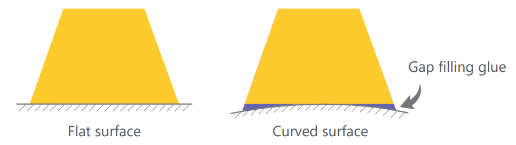

Industrial adhesives such as Loctite 454 can be used to mount the sensor on a flat and smooth surface. If the surface is slightly curved or uneven, a slightly thicker layer of adhesive such as Loctite 3090 or 4070 can be used for gluing the sensor.

Follow closely the instructions that comes with the glue.

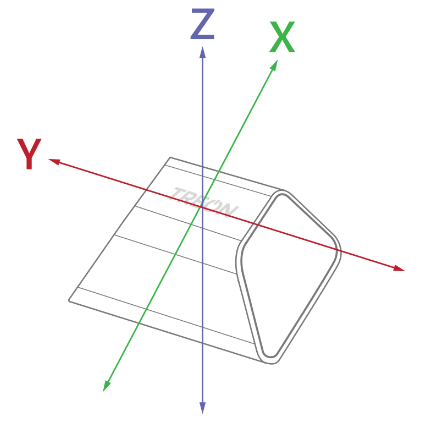

Aligning the sensor

For accurate interpretation of the measurement data of all sensor axis, the centerline of the sensor is typically aligned with the shaft of the rotating machine. When mounting the sensor, align its axis directly toward drive or non-drive end of monitored achine in line with its shaft